Wholesale Discount Hvls Fan Shenzhen - DM 3000 – Apogee

Wholesale Discount Hvls Fan Shenzhen - DM 3000 – Apogee Detail:

Product Advantages

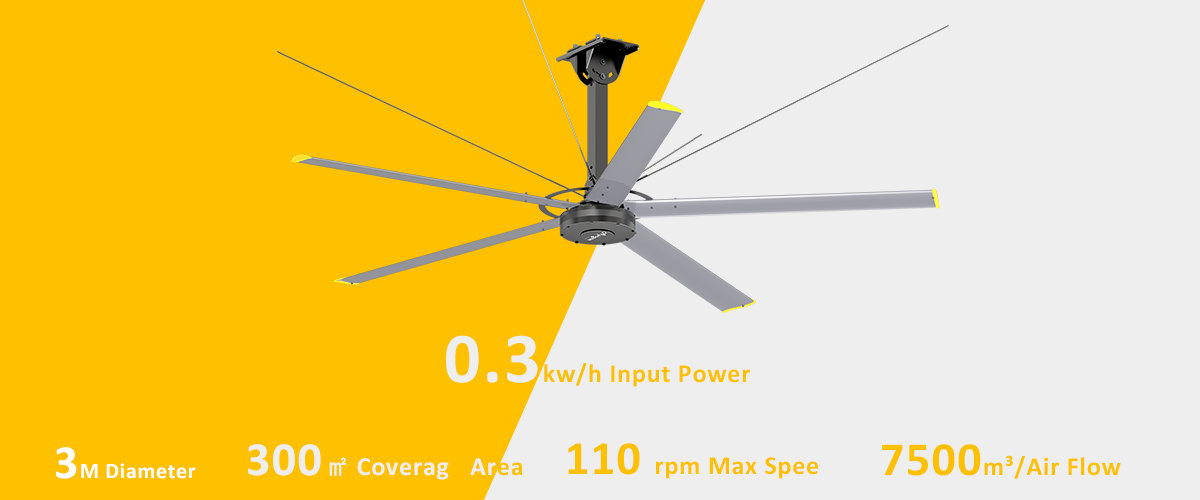

Lower Input Power

Compared with other systems such as gears that require lubricant. PMSM technology adopts a direct drive system driven by a permanent magnet synchronous motor, and changes the polarity of the rotor automatically through a permanent magnet brushless motor, reducing the work, so that the input voltage only needs 0.3KW per hour. Lower input voltage, while providing good ventilation effect, high efficiency and energy saving.

HumidityProof

Apogee DM series HVLS fan drives the airflow to form a circulating flow ring through the rotation of the fan blades, promotes the air mixing in the whole space, and quickly blows and discharges the fume and moisture with unpleasant smell, thereby improving the air quality and obtaining a healthy air, dry environment. It can eliminate birds and bed bugs, as well as avoid the noise, moisture-induced decay, etc. that its ventilation scheme is prone to.

100% Safety Ensure

The PMSM motor adopts the outer rotor high torque design. Compared with the traditional asynchronous motor, the weight of the ceiling fan is reduced by 60kg, which is safer. The anti-collision design is added to the fan brake, which has been adjusted for many times during the development process, which greatly ensures the safety of the product. Apogee’s professional anti-collision device can ensure that the fan stops immediately when it receives an accidental impact to ensure the safety of personnel to the greatest extent.

BLDC Technology

DM series HVLS FAN adopts BLDC technology, which is independently developed by Apogee. It has core patent technology and has obtained relevant patents. The energy efficiency standard of BLDC motor has reached the first-class energy consumption standard in China, with energy-saving and high efficiency, long service life, and wide speed regulation range.

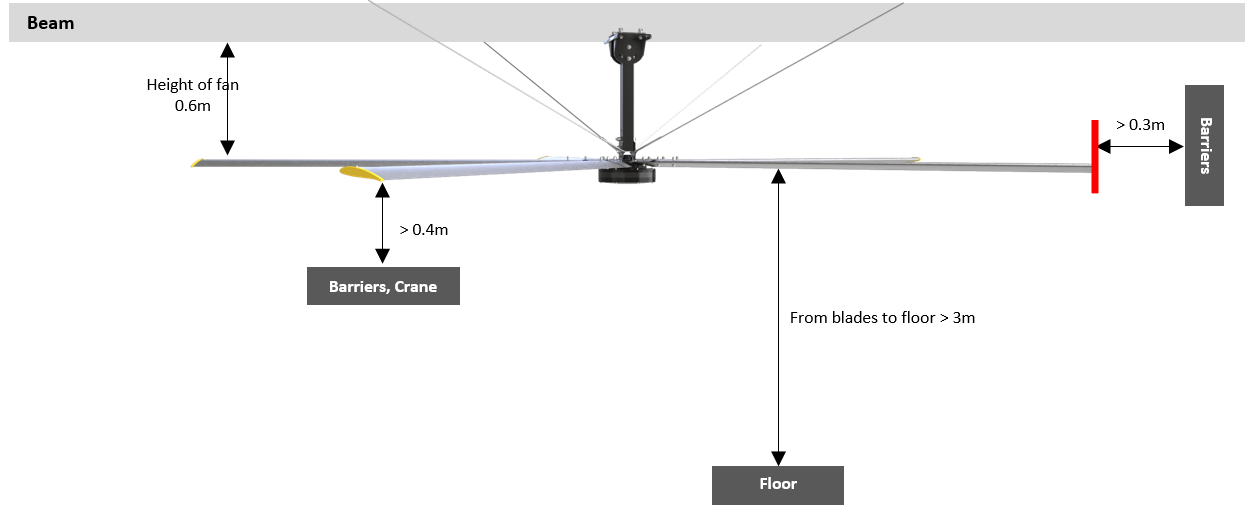

Installation Condition

We have experienced technical team, and we will provide professional technical service including measurement and installation.

1. From blades to floor > 3m

2. From blades to barriers (crane) > 0.4m

3. From blades to barriers (column/light) > 0.3m

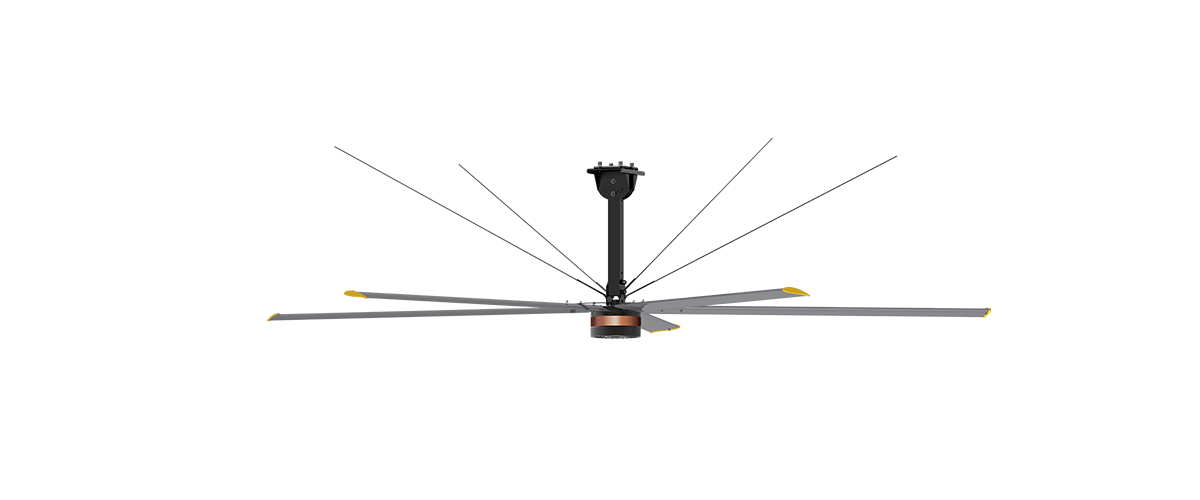

Product detail pictures:

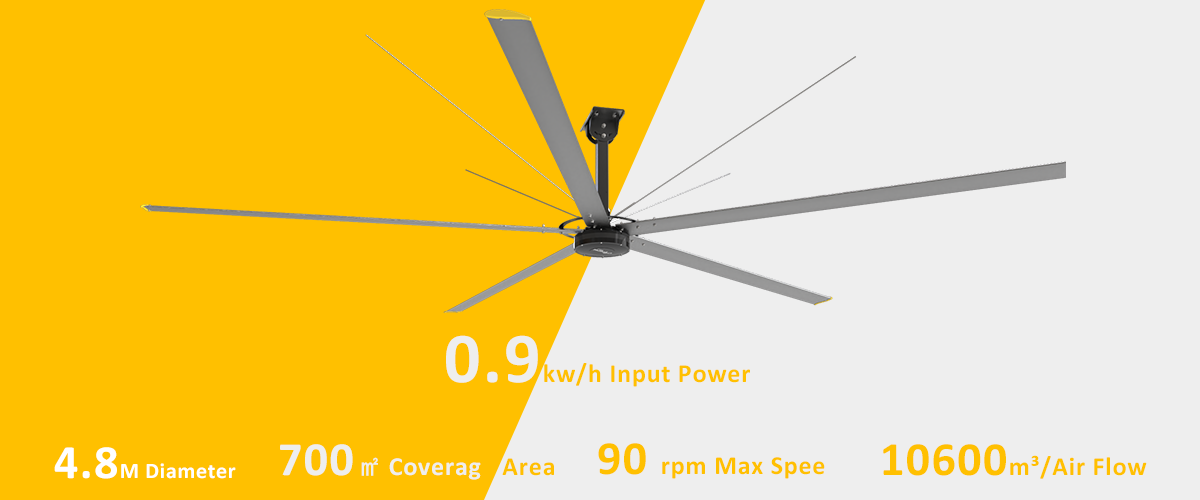

Related Product Guide:

We take pleasure in an extremely fantastic standing among the our prospects for our great product top quality, competitive cost and the finest support for Wholesale Discount Hvls Fan Shenzhen - DM 3000 – Apogee , The product will supply to all over the world, such as: San Francisco, Niger, Turkey, Our products are widely recognized and trusted by users and can meet continuously changing economic and social needs. We welcome new and old customers from all walks of life to contact us for future business relationships and mutual success!

The manufacturer gave us a big discount under the premise of ensuring the quality of products, thank you very much, we will select this company again.