TM Series – SEW Gear Drive Motor

|

TM Series Specification ( SEW Gear driver) |

|||||||||

|

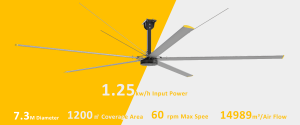

Model |

Diameter |

Blade Qty |

Weight KG |

Voltage V |

Current A |

Power KW |

Max.Speed RPM |

Airflow M³/min |

Coverage Area ㎡ |

|

TM-7300 |

7300 |

6 |

126 |

380V |

2.7 |

1.5 |

60 |

14989 |

800-1500 |

|

TM-6100 |

6100 |

6 |

117 |

380V |

2.4 |

1.2 |

70 |

13000 |

650-1250 |

|

TM-5500 |

5500 |

6 |

112 |

380V |

2.2 |

1.0 |

80 |

12000 |

500-900 |

|

TM-4800 |

4800 |

6 |

107 |

380V |

1.8 |

0.8 |

90 |

9700 |

350-700 |

|

TM-3600 |

3600 |

6 |

97 |

380V |

1.0 |

0.5 |

100 |

9200 |

200-450 |

|

TM-3000 |

3000 |

6 |

93 |

380V |

0.8 |

0.3 |

110 |

7300 |

150-300 |

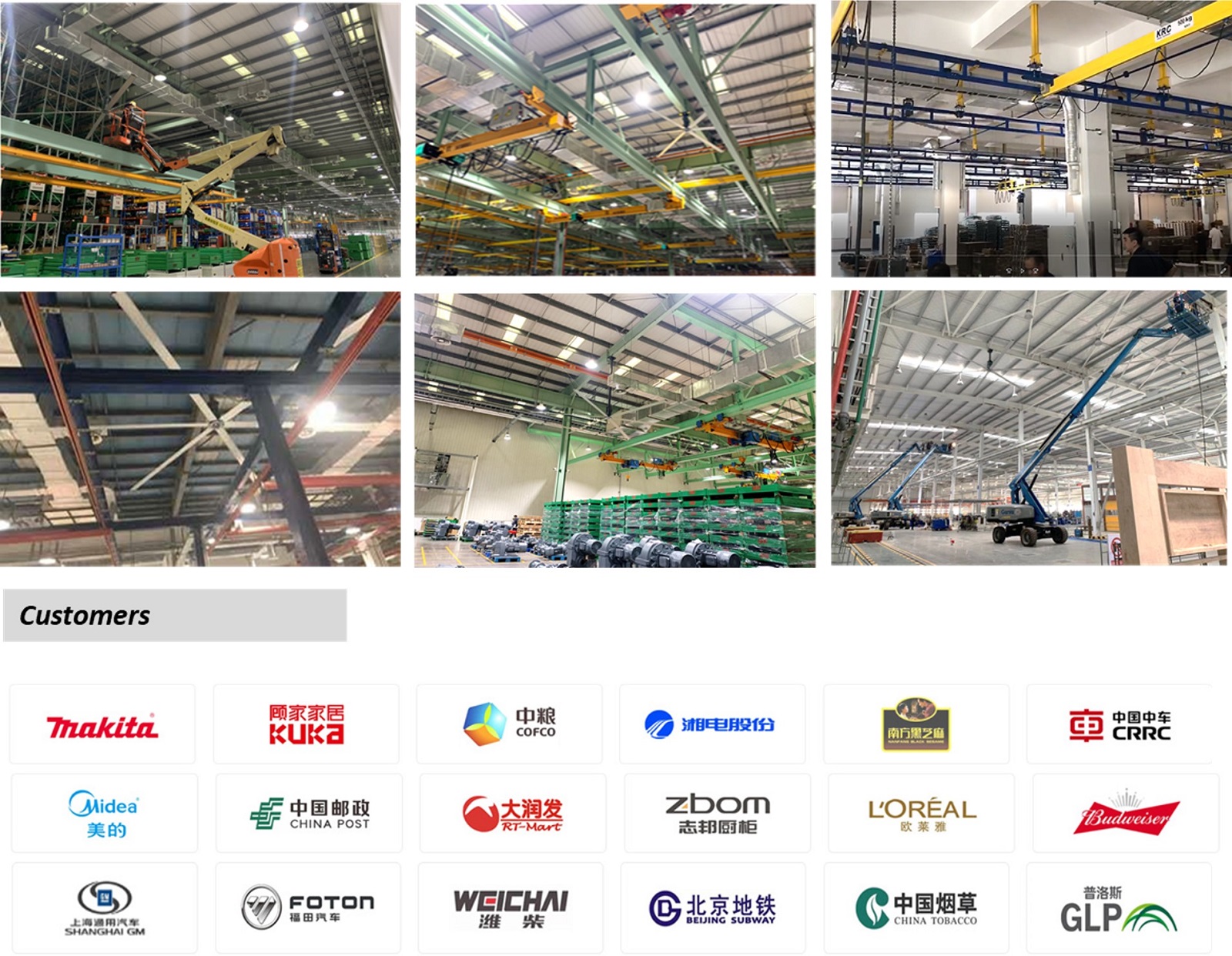

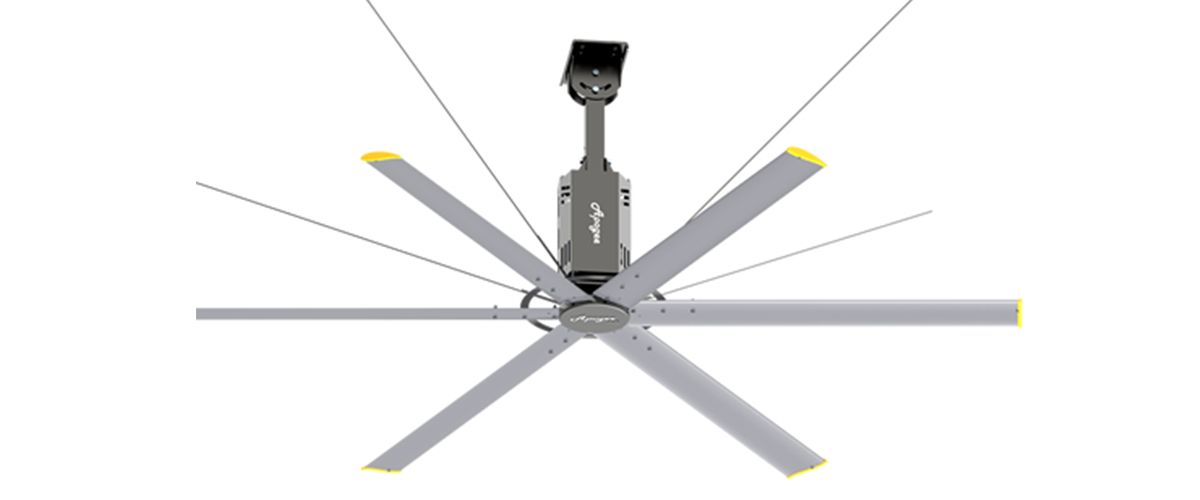

Main Components

1. Gear Driver:

German SEW gear driver is integrated with high efficiency motor, SKF double bearing, double sealing oil.

2. Control Panel:

Digital control panel can display the running speed. It is easy to operate, light in weight and takes up little space.

3. Central Control:

Apogee Smart Control is our patents, able to control 30 large fans, through timing and temperature sensing, the operation plan is pre-defined. While improving the environment, minimize the cost of electricity.

4. HUB:

Hub is made of ultra-high strength, Alloy steel Q460D.

5. Blades:

Blades is made of aluminum alloy 6063-T6, aerodynamic and resist fatigue design, effectively prevent deformation, big air volume, surface anodic oxidation for easy clean.

6

Safety design of ceiling fan adopts double protection design to prevent accidental fracture of fan blade. Apogee special software monitors the operation of ceiling fan in real time

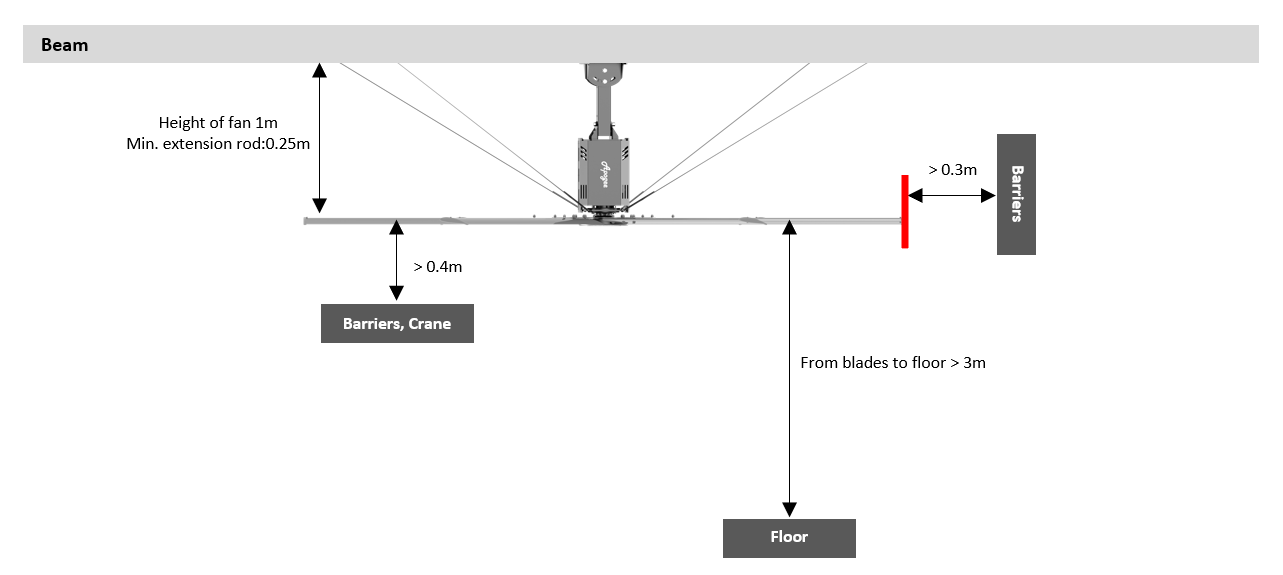

Installation Condition

We have experienced technical team, and we will provide professional technical service including measurement and installation.

Application