Factory Price Hvls Fan Manufacturer - DM 6100 – Apogee

Factory Price Hvls Fan Manufacturer - DM 6100 – Apogee Detail:

Product Advantages

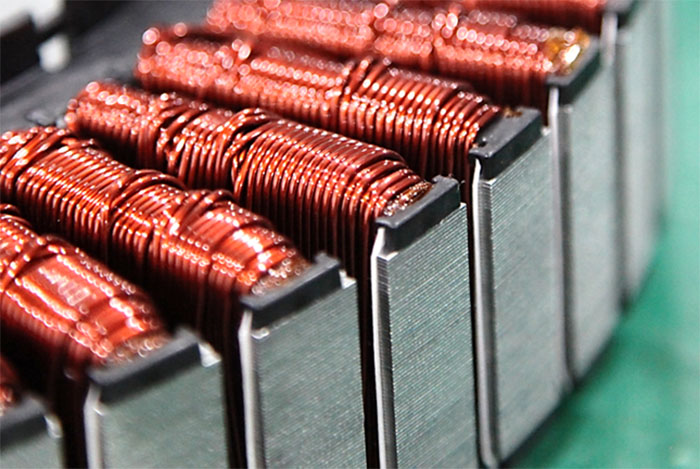

Bldc Core Motor Technology

Apogee HVLS Fan adopts BLDC motor technology, 20 years of permanent magnet brushless synchronous motor technology, and experience based on finite element analysis and self-developed permanent magnet motor and simulation technology. Motor optimization design, optimized production, and high-reliability motor.

Life Time

HVLS fan motor is replaced from the traditional reducer to the newly developed permanent magnet brushless motor, which saves the loss caused by the friction between the gear and the reducer and has a longer service life. The fully enclosed design reduces the erosion of the motor by dust, water vapor and some corrosive gases. Secondly, strict quality management coupled with international-class quality product components and raw materials ensure that the service life of the product is as long as 15 years.

Energy Saving

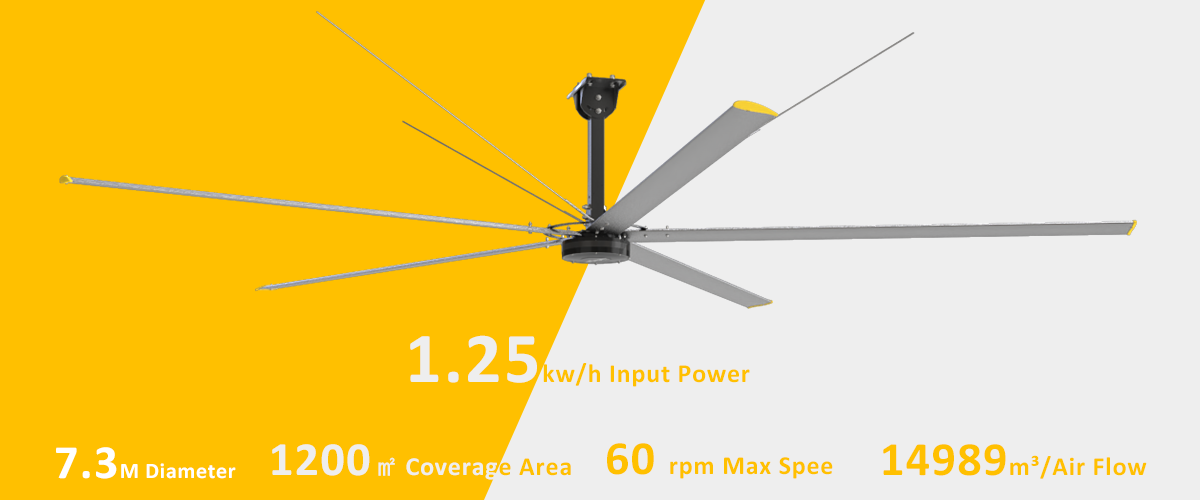

PMSM technology, unique outer rotor high-torque design, eliminates the frictional energy consumption of gear reduction box compared to traditional reducer, directly uses permanent magnet direct drive system, no reduction box, reduces loss, saves 50% energy compared to induction motor ceiling fans with the same function. The input power per hour is only 1.1 kW, which can drive the fan to achieve large-scale air supply and save energy.

Stepless Speed Regulation

Apogee PMSM (Permanent magnet synchronous motor) technology has a wide speed regulation range. The DM-6100 series products have a speed between 10rpm and 70rpm, high-speed cooling (70rpm), and low-speed ventilation (10rpm) to meet the needs of different applications. The ceiling fan can run at low speed for a long-time during operation. No motor temperature rise noise, the whole process of the ceiling fan operation temperature rises vibration detection, safe and reliable.

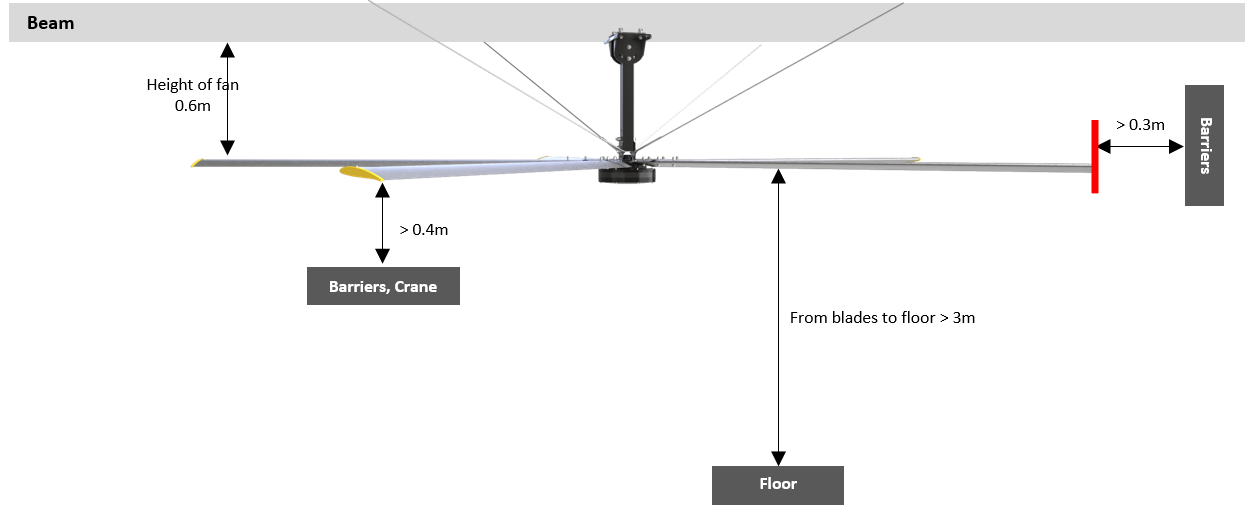

Installation Condition

We have experienced technical team, and we will provide professional technical service including measurement and installation.

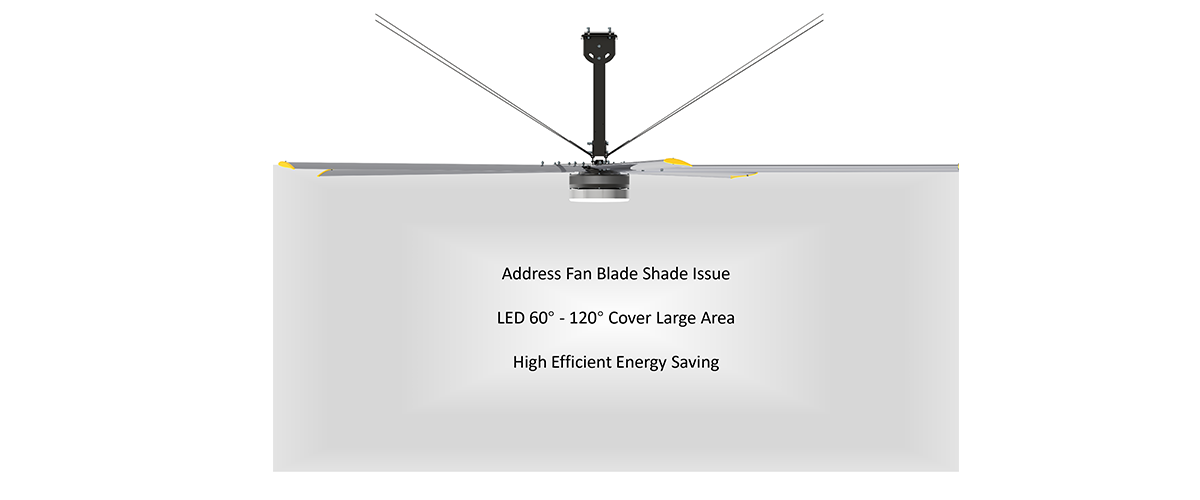

1. From blades to floor > 3m

2. From blades to barriers (crane) > 0.4m

3. From blades to barriers (column/light) > 0.3m

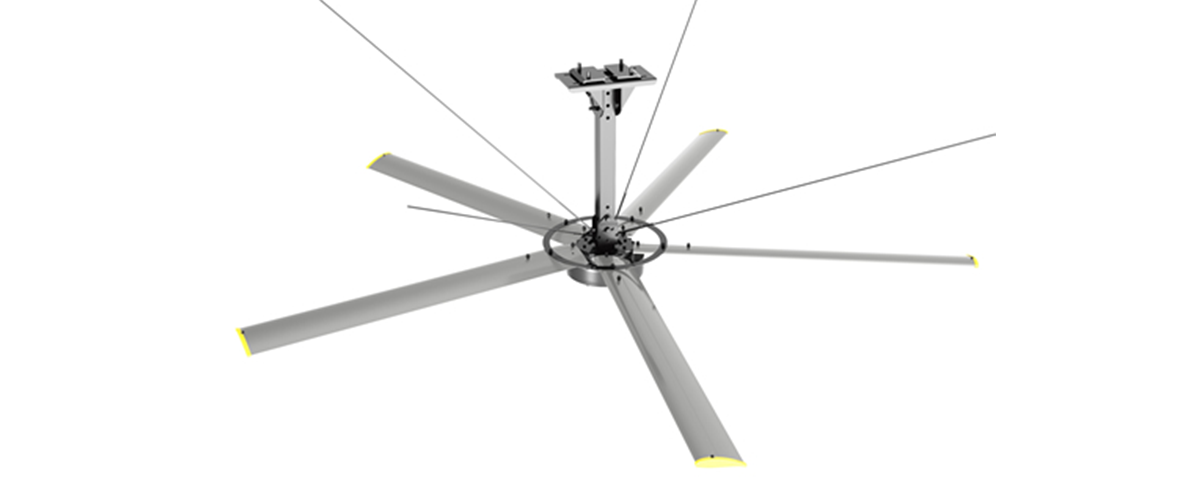

Product detail pictures:

Related Product Guide:

We insist on the principle of development of 'High quality, Efficiency, Sincerity and Down-to-earth working approach' to deliver you with great provider of processing for Factory Price Hvls Fan Manufacturer - DM 6100 – Apogee , The product will supply to all over the world, such as: French, Amsterdam, Mombasa, Our products have mainly exported to south-east Asia Euro-America, and sales to all of our country. And depending on excellent quality, reasonable price, best service, we have got good feedback from customers overseas. You are welcomed to join us for more possibilities and benefits. We welcome customers, business associations and friends from all parts of the world to contact us and seek cooperation for mutual benefits.

After the signing of the contract, we received satisfactory goods in a short term, this is a commendable manufacturer.